Super

Fine.

Mean particle d 50% as small as 1.9 µm.

At this size, your calcium carbonate masterbatch is capable of being incorporated for any polymer blend for any applications. The final result will always a flawless surface, no matter how thin.

Food-contact

Safe

All of our premium grade filler masterbatch are food-contact safe according to FDA guidelines.

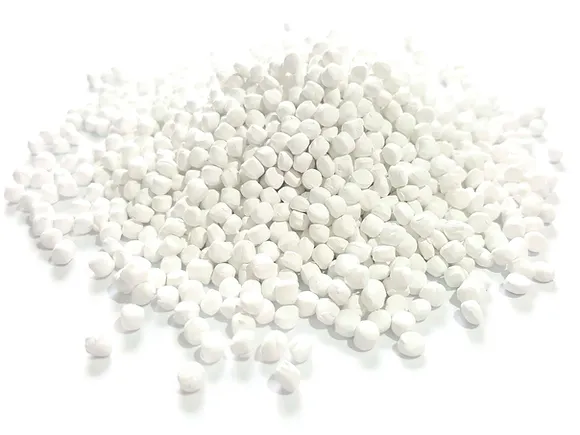

Like other mineral fillers,

calcium carbonate masterbatch

Reduce cost

Calcium carbonate is about ten times cheaper than plastic so more filler content equates to more competitive cost.

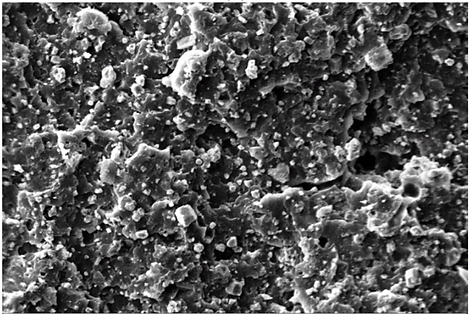

With the incorporation of calcium carbonate masterbatch, some calcium carbonate will distribute at the surface layer of the plastic article to add roughness on a microscopic level, the finer the particle, the more expensive the roughness feel.

Enhances rigidity

The addition of calcium carbonate gives a denser structure and contribute the the entire polymer system’s stiffness due to its natural hardness as a mineral. Furthermore, because it is so small, the CaCO3 itself also functions as a nucleating agent that increases the crystallinity of the polymer matrix and hence, improving the overall stiffness and scratch resistance property.

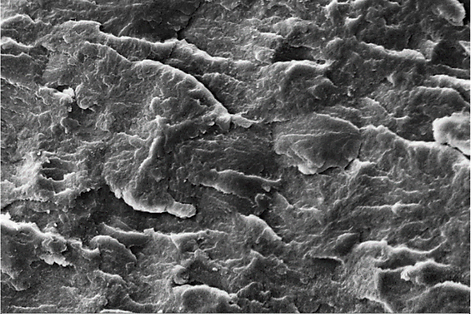

SEM Micrograph 1000x magnification

Unfilled PP

30% CaCO3 filled PP

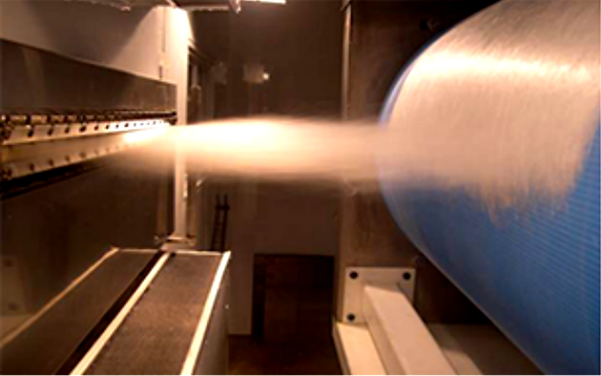

Reduces cycle time

Plastic by itself is an insulator so by adding a mineral filler like calcium carbonate, the entire melt suddenly got enhanced thermal conductivity that allow it to heat up faster and cool down quicker which as a result reduce cycle time. This effect is even magnified by our micron-size filler that fills in the gaps between polymer particles better.

There’s a filler masterbatch for any applications.

Everything from masks, diapers, and high-speed thin gauge film, to toys and food containers. Anything from spun-bond, melt-blown to injection molding, extrusion, and blow molding.

We got the right filler masterbatch to help you optimize cost..

Ask an expert.

Let’s get in touch.